Description

- обладает повышенной глубинностью;

- легко извлекается при прихватах;

- имеет питание от батарей, не чувствительна к свойствам и качеству бурового раствора;

- работает на аэрированных растворах и при продувке воздухом;

- легко преодолевает неблагоприятные для электромагнитного канала разрезы (солевые, угленосные пласты).

Технические характеристики

| Параметры | Диапазон измерений, погрешность |

|---|---|

|

|

Угол установки отклонителя, град.

|

|

| Диапазон измерения мощности экспозиционной дозы (МЭД) естественного гамма излучения, мкР/час | 1-100 (±15%) |

| Максимальная рабочая температура, °С | 120 |

| Максимальное гидростатическое давление, МПа | 60 |

| Минимальный внутренний диаметр бурильной колонны, мм | 53 |

Габаритные размеры телесистемы, мм:

|

|

Масса составных частей телесистемы, кг:

|

|

В качестве корпуса забойного блока применяется стандартная немагнитная УБТ, в качестве корпуса ретранслятора - стандартная ТБТ.

Принцип работы телесистемы ЗТС-42КК

Телеметрическая система с комбинированным каналом связи получила широкое распространение сравнительно недавно (с 2008 г) и принцип ее работы известен далеко не каждому. Поэтому ниже в доступной форме и максимально кратко мы постарались изложить его суть.

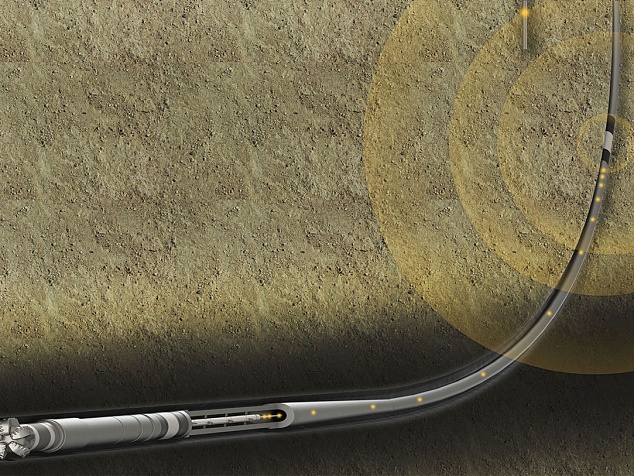

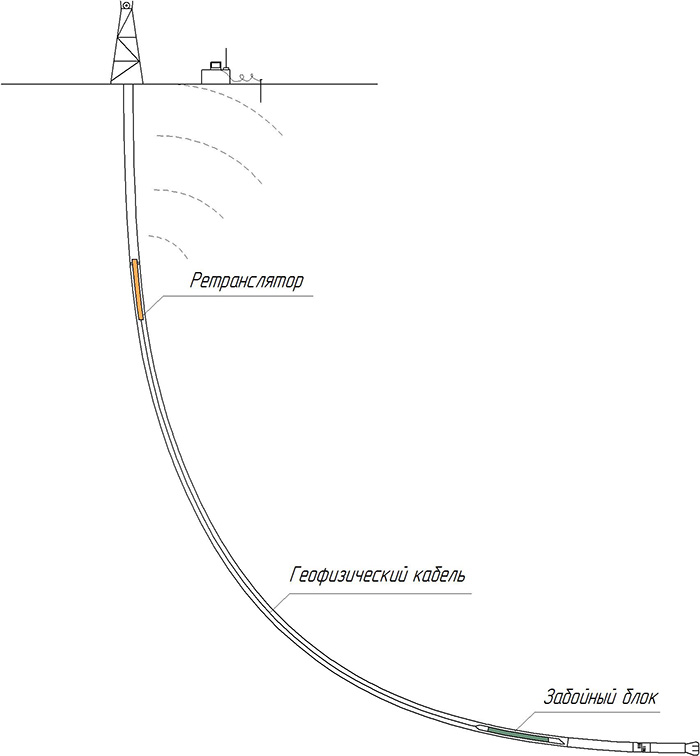

Комбинированным канал связи данной телесистемы назван потому, что сочетает передачу данных последовательно двумя способами – сначала от забоя по кабелю и далее на поверхность по породе с помощью электромагнитных волн. Схематично компоновка бурильной колонны с телесистемой показана на рисунке ниже.

Забойный блок имеет в своем составе датчики инлинометрии, вибрации и ГК. Дополнительно могут устанавливаться модули нейтронного каротажа и резистивиметрии, а также наддолотный модуль. Данные от забойного блока передаются по кабелю до ретранслятора, который устанавливается обычно на небольшой глубине. С ретранслятора данные отправляются на поверхность с помощью электромагнитного канала связи. Ретранслятор при этом может находиться как в открытом стволе, так и в обсадной колонне. Таким образом, от забоя до устья данные, зафиксированные датчиками телесистемы, идут последовательно по двум разным каналам – сначала по кабельному, затем по электромагнитному.

У данного вида канала связи есть ряд преимуществ. Во-первых – это увеличенная по сравнению с чисто электромагнитным каналом глубинность. Длина кабельной секции обычно берется по максимуму с учетом некоторых ограничений. Во-вторых – извлекаемость, причем не просто теоретическая, а многократно проверенная на скважинах. Это особенно важно при работе с источниками ионизирующего излучения. Третье преимущество – независимость от циркуляции и свойств бурового раствора за счет использования питания от батарей. Четвертое преимущество – независимость от электрических свойств горных пород, к которым весьма чувствительны телесистемы с электромагнитным каналом связи.

Спуск бурильной колонны при использовании данной телесистемы начинается со сборки КНБК, навинчивания немагнитных утяжеленных труб и ориентационного переводника, в который впоследствии спустится на кабеле забойный блок. Далее производится спуск бурильного инструмента до определенной глубины, на которой устанавливается ретранслятор. С помощью геофизического подъемника, входящего в состав оборудования наших телеметрических партий, производится спуск забойного блока на кабеле. Продолжительность данной операции зависит от глубины спуска и находится обычно в пределах 0,5…2,5 ч.

После посадки забойного блока в ориентационный переводник кабель отрубается, на его конце монтируется соединитель, который подключается к ретранслятору.

Ретранслятор навинчивается на бурильную колонну, и спуск инструмента производится далее до забоя.

Наличие кабеля никак не ограничивает действия бурильщика, компоновку с телесистемой можно вращать до 80 об/мин при соблюдении ограничений, наложенных на забойный двигатель его производителем.

Более подробно об особенностях работы, имеющихся типоразмерах, стоимости оборудования и услуг вы можете узнать, обратившись к нам.

Благодарим за интерес к нашей аппаратуре.